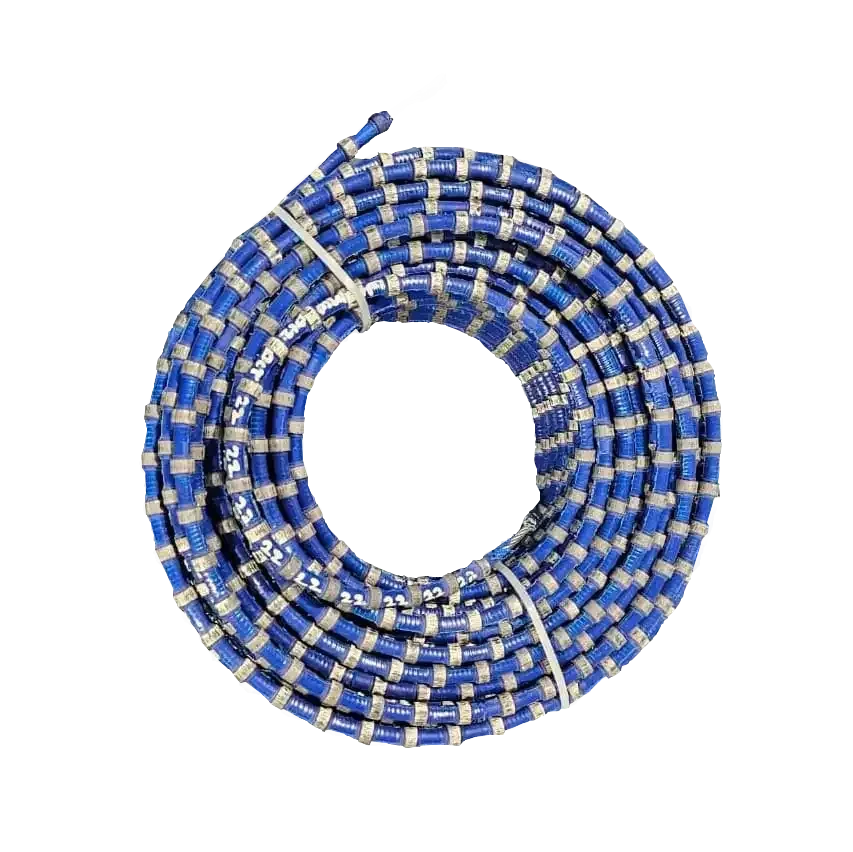

Diamond Wire Tools

Midwest's Diamond Wire Tools segment is dedicated to the design, development, and manufacture of advanced diamond wires, which are used for precision cutting in the natural stone, construction, and related industries. Originally established to support the company’s Natural Stone segment, the Diamond Wire Tools division has since expanded to cater to both captive consumption and external market demand across India's mining and construction sectors.

200,000 metres of diamond wire produced annually.

In-house R&D team focuses on material innovations and process improvements.

Expanding domestic market share with future plans for overseas expansion.

Market & Growth

- Heavy mineral sands contain key minerals such as ilmenite, rutile, zircon, and monazite, which are crucial for titanium-based products in industries like aerospace, electronics, and paints.

- Midwest has expanded its heavy mineral sands operations through its subsidiaries in Sri Lanka, with a planned production capacity of 37,000 MTPA, strengthening its presence in the global market.

- India plays a significant role in the heavy mineral sands market, with deposits concentrated along coastal areas.

Market & Growth

- Production of Diamond Wire at a facility in Hyderabad, catering to both captive and external customer needs in the mining and construction industries.

- Aiming to increase market share through product enhancements and targeting new operators with a ‘concept selling’ strategy.

- Focused R&D team dedicated to improving cutting speed and useful life of Diamond Wire by modifying key material compositions.

- Production of Diamond Wire at a facility in Hyderabad, catering to both captive and external customer needs in the mining and construction industries.

- Aiming to increase market share through product enhancements and targeting new operators with a ‘concept selling’ strategy.

- Focused R&D team dedicated to improving cutting speed and useful life of Diamond Wire by modifying key material compositions.

Products

Specifically designed for dimensional stone quarries, this wire functions as a cutting tool in wire saw machines.

Applications

Source: CRISIL Report

- Quarries

- Processing facilities

- Construction sites

- Quarry Wire: Cutting of Granite blocks in Mine

- Multi Wire: Cutting of Blocks into slabs in factory

- Mono Wire: Trimming of block edges in factory

Key Features & Benefits

Material Composition:

Made using premium materials, including tungsten, iron, cobalt, and synthetic diamonds, optimized for cutting speed and tool longevity.

Energy Efficiency:

Reduced energy consumption due to advancements in process parameters, which also contribute to cost efficiency.

Customizable Design:

Tailored for specific mining and processing needs, ensuring maximum operational efficiency.